Kazakhstan Office

Production Chemical

Microdistrict 26

Building 6 App 48

Aktau, Kazakhstan

Uganda Office

Plot 2, 4th Street Industrial Area

Kampala

Uganda

PO Box 2537, Kampala, Uganda

Production Chemical Solutions DMCC

1306-

Cluster W,

Jumeirah Lakes Towers,

Dubai United Arab Emirates

T: + 971 50 541 7205

Libya Office

Production Chemical

Building No.7

P.O.Box: 3820

Venessa Street

Garyounis

Benghazi, Libya

USA Office

Production Chemical

14071 Peyton Dr, No. 429

Chino Hills

CA 91709

United States

PRODUCTION CHEMICAL GROUP © 2024 All rights reserved. Privacy & Data Protection Policy

PC Nano Coating

FIND OUT MORE

For information on any of our products or services please use our enquiry form or contact your nearest regional office.

PC Nano Coating

A specially formulated advanced “NANO” composite coating combined with our specialised insitu pipeline application techniques, which results in an ultra-

Nano Coating is the process of applying nanostructures to surfaces for the purpose of sealing them on a nanoscopic scale. This coating layer thickness in typically between 1-

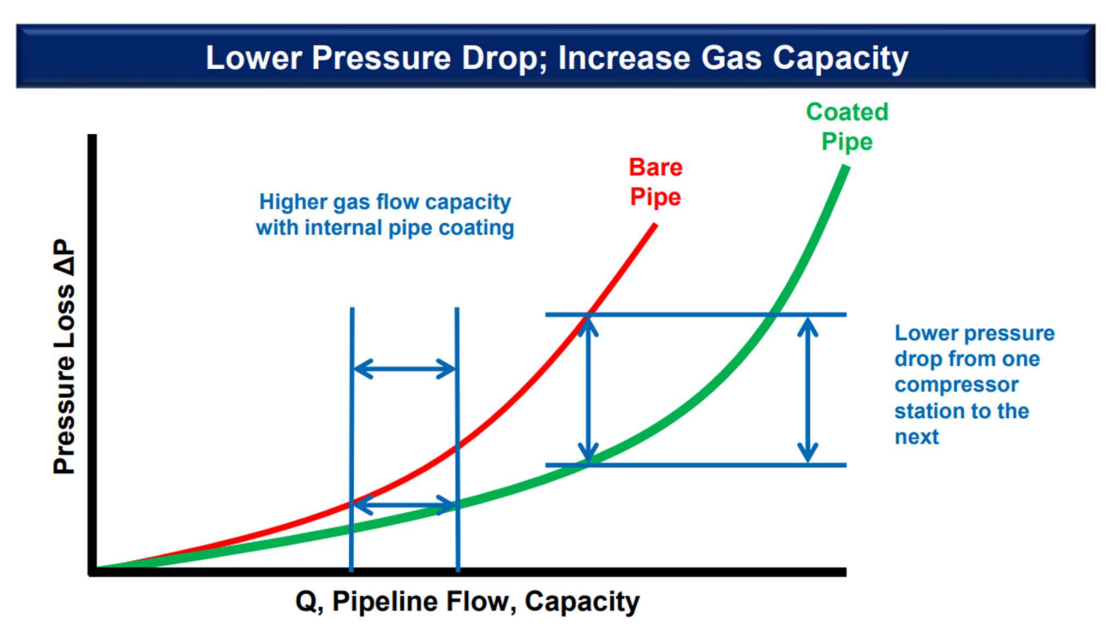

Rougher pipes cause large pressure drops, higher energy input and reduced capacity. With PC Nano Coating the smoother surface creates laminar flow at the internal boundary, thus helping to achieve maximum flow capacity.

Advantages of PC Nano Coating:

• Advanced nanocomposite coating is unlike any traditional coating commercially available

• Proprietry specialty formulated coating with manufacturing capabilities in US and Singapore

• Superior specialized application expertise and techniques that can be performed in-

• Meets International specification API 5L2 for factory internal coating of gas transmission pipelines

• Minimal surface preparation and out-

• Abrasion resistant, not damaged by routine pigging and ILI inspection tools

• Predictive and measurable performance increases can be estimated, and actual results documented after line put back in service.